Lab Talk

June 2012

June 2012

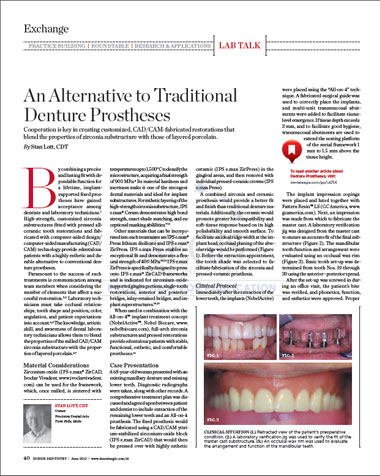

High-Strength, Metal-Free Alternative to Traditional Denture Prostheses. Innovative techniques provide long-term and patient-pleasing results.

By Stan Lott, CDT, AACD

By Stan Lott, CDT, AACD

Inside Dental Technology

March 2012

March 2012

High-Strength, Metal-Free Alternative to Traditional Denture Prostheses. Innovative techniques provide long-term and patient-pleasing results.

By Stan Lott, CDT, AACD

By Stan Lott, CDT, AACD

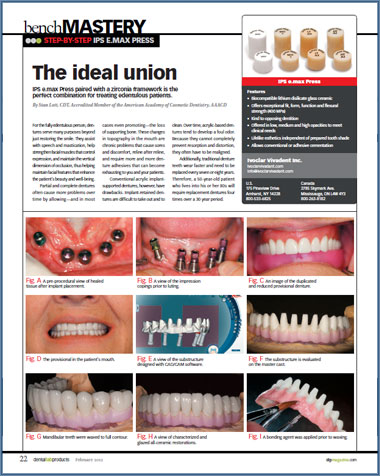

Bench Mastery

February 2012

February 2012

The ideal union IPS e.max Press paired with a zirconia framework is the perfect combination for treating edentulous patients.

By Stan Lott, CDT, Accredited Member of the American Academy of Cosmetic Dentistry, AAACD

By Stan Lott, CDT, Accredited Member of the American Academy of Cosmetic Dentistry, AAACD

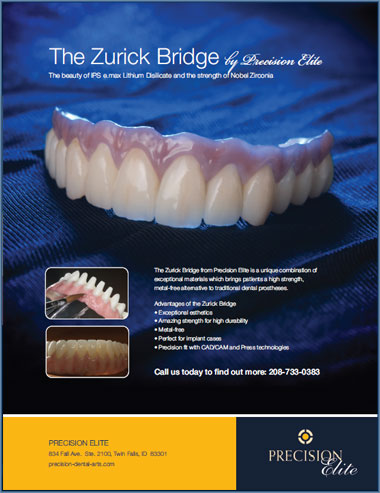

The Zurick Bridge

by Precision Elite

by Precision Elite

The beauty of IPS e.max Lithium Disilicate and the strength of Nobel Zirconia. The Zurick Bridge from Precision Elite is a unique combination of exceptional materials which brings patients a high strength, metal-free alternative to traditional dental prostheses.

Advantages of the Zurick Bridge:

Advantages of the Zurick Bridge:

- Exceptional esthetics

- Amazing strength for high durability

- Metal-free

- Perfect for implant cases

- Precision fit with CAD/CAM and Press technologies

Esthetic and Functional Harmony

The first priority of laboratory technology as it relates to cosmetic dentistry is proper function. Any cosmetic treatment plan needs proper occlusal records, lateral and protrusive movements, and correct maxilla-condyle relationships to help ensure long lasting results. This is critical as we employ laboratory techniques or systems of any kind. Indeed, esthetics minus function equals failure.

Dental porcelain systems have made quantum steps forward in an effort to mimic nature in color, form, and function. Chemists are continually creating stronger and more durable porcelains.

Materials such as silicon

nitride, quartz, alumina particles, and

lucite are being added to conventional ceramics.

In some all-ceramic systems, totally new

chemical structures are being introduced.

These include glass-ceramics, crys-

talline hydroxyapatite, tetrasilic, fluormica

(machinable ceramics), zirconia, and lucites.

One of the strongest materials is an infiltrated

glass. Perhaps the most interesting material

to date is a single-phase hydrothermal ceramic.

The advantages of an all-ceramic restoration compared to a ceramo-metal crown are many indeed. The transmission and dispersion of light through an all-ceramic bonded restoration imitates the "natural" appearance of translucency, vitality, and depth of color. This creates a better harmony with existing dentition that the discerning patient and doctor will appreciate.

The absence of metal substructures eliminates other problematic behavior such as:

- A "dark margin" appearance.

(although porcelain margins will help significantly) - Greying of thin translucent gingiva.

- An "opaque look" due to inadequate reduction.

- A monochromatic appearance.

Ducera, Inc., of South Plains, New Jersey, has introduced a

new category of ceramic. It is a single-phase,

hydrothermaldental ceramic called Low Fusing Ceramic, (LFC).

The manufacturer makes the following claims:

"The transmission

and dispersion of light through an

all-ceramic bonded restoration imitates

the "natural"

appearance of translucency, vitality, and

depth of color."

First, it is 47% stronger in flexural strength than metal ceramics. Due to an ion exchange surface layer inherent to this porcelain, it increases its strength in vitro. Other porcelains decrease in strength, especially at the ten to twelve year period as hydraulic pressure turns micro cracks into macro cracks that propagate under stresses such as thermal, load fatigue, or design.

In recent years, the all-ceramic restoration

has become the restoration of choice whenever

possible. This was primarily brought about

by the developments of resin luting cements

and dentin bonding agents.6 Coupled with

these are the before-mentioned reinforced

porcelain systems. The

success of the bonded restorations are well-documented

and studies do agree on the exceptional

effectiveness of this modality in both functional

and esthetic treatments.

Second, low firing temperatures allow a better, more stable, natural color format. The translucency is not clouded, opalescence is true to the ceramic and not a metallic oxide fritting.9 Light dispersion is very natural and similar to tooth structure.

Third, the homogenous and extremely dense nature of this ceramic material makes it easy to grind, and it polishes extremely well. This softer porcelain is unique in that all test results indicate it is "most like natural enamel" in functional wear properties.9 This creates a much less abrasive occlusal surface and enhances periodontal tissue health.

In our laboratory. Low Fusing Ceramic is utilized to encase ceramo-metal and all-ceramic restorations as per the manufacturer's recommendations. I have been very im pressed with the results of this new material. If the laboratory testing does extrapolate into every day clinical results, I perceive it to be the restoration of choice among the discerning dentists of tomorrow.

Although there are many porcelain systems on the market today, no system should be expected to be all-encompassing. Some systems function and/or appear different under certain circumstances."' Thus the integrity and talent of the ceramist-technologist will always be the critical factor in our pursuit of excellence.

Pursuant to this cooperative goal of naturally beautiful and functional smiles is good communication between the dental office and laboratory. Visual communications are perhaps the most convenient to use and best convey details and the expectations of the patient and doctor. Photographs, laboratory prescriptions, computer imaging, color mapping, study models, or videos are tools of necessity to obtain optimum clinical results.

The following cases incorporate the before mentioned materials along with some of these ideas.

This patient expressed a strong interest in remaking a poorly constructed porcelain to metal restoration on tooth #8, (non-vital) which had been completed just a few months prior. He also expressed a strong desire to close the diastema between #8 and #9, correct the rotated appearance of ft 7, and create a better overall color and contour harmony in the maxillary anterior region. At this point, photographs and study models were taken.

It was concluded that in order to reduce anterior stresses, slight coronal plasty w^ould be done on the mandibular lat erals and central and veneers would be made for teeth #7 and #9, along with the replacement of #8 with an all-ceramic restoration. This conservative approach proved to produce good results in restoring proper colors and contours.

An initial enamel reduction of 0.5 mm was

done using a LVS-1 Brasseler diamond bur.

The remaining facial bulk enamel was reduced.

Final preparations included a tape ing chamfer

that extended to the edge of the retracted

gingiva on each veneer. Tooth #9's preparation

did not

break the distal contact and a lingual margin

was established. Toward the mesial lingual,

the margin was again brought down to the

retracted gingiva to provide for the mesial

emergence profile. Tooth #7 was prepared

in much the same fashion; slightly more

reduction was made to the mesial facial

lobe for a more ideal contouring of the

veneer. Tooth #8 had previously been prepared

and only minor changes were made to "clean

up" the margins.

With the retraction cord in place on #7

and #9, the second cord on #8 was removed,

and a polyvinylsiloxane impression was taken

along with an

opposing arch. I was called to the office

to determine the shades to be utilized.

First, I wanted to closely match the adjacent

prepared teeth in color

and the degree of opacity exhibited bv ff7

and 9 at the same depth. A previously fabricated

shade tab was used, consisting of a 1:1:1

ratio of B-2, D-2, and D-3 opacious dentin,

and it was mixed with a 20% 1:1:1 ratio

of B-2, D- 2, and D-3 dentin." It was

determined that this should be used to build

up &8 and that a D-2 shade, plus a slight

ochergingival tone and an opal incisal halo

would blend in well.

Model and Die Work

Models and dies along with a soft tissue

model were prepared. The dies were trimmed

under a 10X stereo microscope. The dies

are painted with a removable varnish to

allow about 35

microns space for resin. All saw cuts were

then blocked out and an impres-

sion was made with Express STD (vinylpolysiloxan).

The refractory

material was then mixed, vibrated into place,

and allowed to set for 45 minutes. The cast

was then removed and trimmed that it might

be incorporated in an Accu-Trac tray with

additional refractory material and allowed

to dry. The tray and refractory are then

separated, sectioned, and trimmed to facili

tate the ease of handling and access to

the interproximal margins.

The dies are placed in the oven at about

400 degrees C to eliminate ammonia

from the refractory that otherwise would

severely contaminate the porcelain. The

margins are then marked and fired to place.

The "cure" bake

(stabilization and expansion) is performed

at 980 degrees C. The second

bake is that of a wash-bake nature at 925

degrees C to adhere the porcelain

into the micro porosities of the refractory

material itself; thus the porcelain

will not separate or pull away from the

die due to "porcelain creep" upon

vitrification. I believe these first two

firings are crucial for three reasons:

the tray, condensed, fired at 500 Degrees

C to 915 degrees C at a six

minute rise under vacuum, and then air fired

at 915 degrees C for 1 minute.

First, to insure intimate margin adaptation;

second, a well condensed and

homogenous internal surface; third, establish

basic color tones. Next, I set out the porcelain

palate. Remember, I want to build up #8

to mimic somewhat the prepared teeth #7

and #9. This was done and fired into place.

The corresponding shades were mixed to follow

the prescription. First a D-2 plus a slight

amount of ocher porcelain modifier was placed

on the cervical margins and a basic D-2

dentin build up was made along with the

D-2 +1 /4 B-l dentin that was also prescribed.

A vertical segmental layering was applied

with very little mammalon development. An

incisal 50 and 51 were used along with a

thin overlay of window, and opal incisal

was added to form a whitish halo effect.

Each was then removed fromthe tray, condensed,

fired at 500

Degrees C to 915 degrees C at a six minute

rise under vacuum, and then

air fired at 915 degrees C for 1 minute.

Contour and Glazing

The restorations were contoured to close

the diastema and correct the rotation on

#7. All surfaces were then layered with

LFC transparent and fired. Slight surface

texture was done with a med.-coarse diamond

point, and a final LFC glaze was done. The

contacts were checked, and the veneers and

all porcelain restorations were separated

from the refractory via Al

0 (25 micron) at 30 Ibs. psi.

They were each tried on the master dies and model. A slight contact adjustment and a slight margin overhang on the lingual of #8 was refined. All margins were checked for correct contours. Any adjustments at this point were done with a white rubber wheel and polished with diamond paste. Each was etched and silanated and delivered to the doctor for placement.

The patient's primary complaint and reason

for seeking treatment was that

#8 and #9 were too broad, and lighter in

value than her smaller-than-normal,

grey-appearing laterals. The yellow chroma

of the cuspids was stronger than any of

her remaining teeth. Isolated bleaching

was performed on #7 and #10 along with a

full lower bleaching treatment. At this

time a photo was taken for laboratory communication.

The teeth were prepared and another photo was taken to show the color and density of color along with other char acterization of the remaining tooth structure.

Polychromatic Layering of Porcelains

Porcelain placements consisted of a 1:4 mixture ofB-2 Opacous Dentin and B-2 Dentin, plus a touch of light yellow (to bump up the chroma and value slightly). The basic B-2 Dentin layer was verv thin and interspersed with a B-l lobe here and there. It was then brushed back from the labial incisal 1/3 of the build up. Then a vertical segmental incisal placement was done alternating a 1:2 ratio mix of window (clear), and [ncisal 50 (light blue-grey), with a 1:2 ratio mix of window (clear), and Incisal 51 (light grey), and a touch of T-5 (polar blue). Each build-up was removed. Enamel shaded contact areas were placed. The porcelain was condensed with vibration and moisture removal (tissue blot technique), then fired from 500 degrees C to 915 degrees C in 6 minutes vacuum with a 1 minute air fire at 915 degrees C.

Although this technique of multiple building and firing is more time consuming, it offers a system of checks and balances relative to the location of final crown contours, colors, and the appearance of enamel depth that looks natural.

Contour and Glazing

After firing the veneers, contacts were adjusted, final contours were established, and surface texture completed. The margins were also finished at this time.

An initial glaze was done with LFC glaze at which time a light opal halo was placed on each restoration and a few light to moderate decalcification (white) areas were added. Note: LFC stains are a fitted porcelain and metal oxide composition and not a metal oxide only. Thus they do not wear off or leach out as many conventional stains do over 4-7 years.9 When staining, a double glaze is a good idea with strong merit. A second LFC glaze was done, and the veneers are removed from the refractory via Al 0 (25 micron) and 30 Ibs. psi. Each was etched and silanated for delivery.

Conclusion

This new single-phase hydrotherrnal dental ceramic, coupled with sound techniques and polychromatic layering will create superior esthetic results. The physical properties and wear characteristics most closely match that of natural dentition of any tooth colored restorative available. You can ensure vour patients function and esthetics for years to come.